Understanding the Role of Electrical Connectors in Modern Vehicles

When it comes to automotive systems, electrical connectors are often the unsung heroes keeping everything running smoothly. We have witnessed how these small, often overlooked components enable complex electrical circuits to function reliably. From powering headlights to integrating advanced driver assistance systems, electrical connectors form the backbone of a vehicle’s electrical network.

In today’s cars, the complexity is staggering. A typical vehicle contains hundreds, sometimes thousands, of electrical connectors designed to facilitate seamless connections between wiring harnesses, sensors, and control units. These connectors must withstand harsh environments involving heat, vibration, moisture, and chemical exposure, especially in a place like Nevada where temperature extremes are common.

Our passion for understanding electrical connectors has shown us their critical influence on vehicle safety, performance, and maintenance. Faulty or corroded connectors can lead to intermittent electrical faults, causing issues ranging from minor annoyances to major safety hazards. That’s why grasping the fundamentals of electrical connectors is essential for both car enthusiasts and professionals alike.

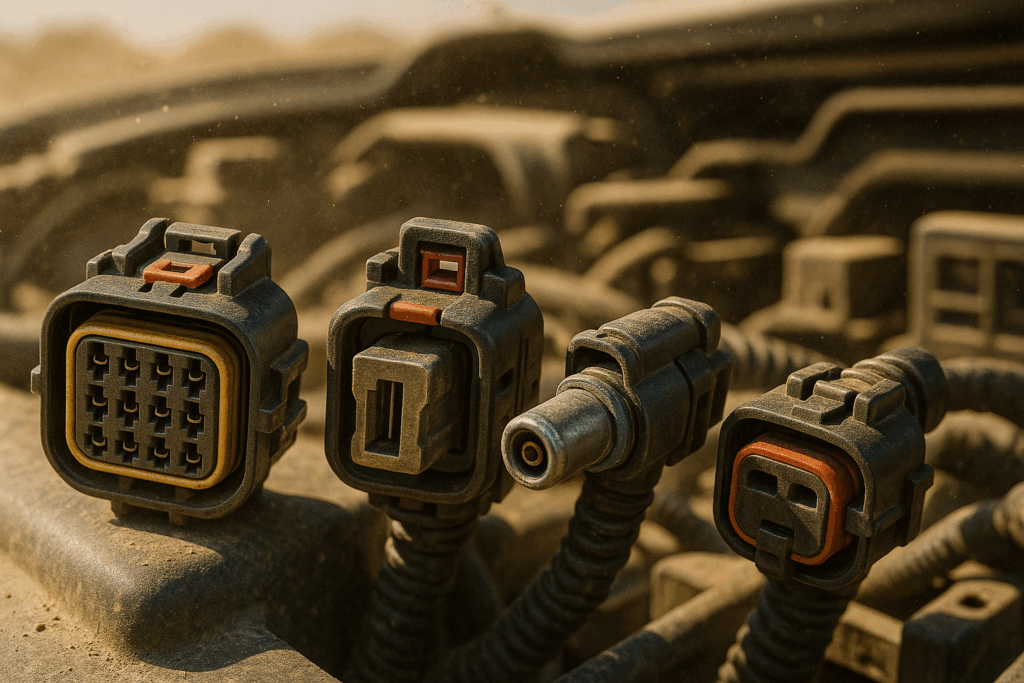

The Different Types of Electrical Connectors Used in Cars

Cars utilize a variety of electrical connectors, each designed for specific functions and environmental demands. Knowing these types helps us appreciate their importance and select the right connectors for repairs or upgrades.

Pin and Socket Connectors

Pin and socket connectors are among the most common in automotive wiring. They consist of metal pins housed within plastic shells, providing secure physical and electrical connections. These connectors often feature locking mechanisms to prevent accidental disconnection, which is crucial in a moving vehicle.

Advantages include easy mating and disconnection, resistance to vibration, and clear polarity identification. In Nevada, where dust and heat can challenge electrical components, high-quality pin and socket connectors with sealing features help maintain reliability.

Blade and Spade Connectors

Blade or spade connectors are flat metal connectors that insert into corresponding slots. These are commonly used for simple connections, such as in fuse boxes or lighting circuits. While convenient and quick to use, they might not provide the highest level of protection against moisture or vibration unless paired with protective covers.

Coaxial and Specialty Connectors

For signal transmission, particularly in infotainment and navigation systems, coaxial connectors are prevalent. These connectors maintain signal integrity, shielding against electromagnetic interference. Specialty connectors designed for airbags or engine sensors are engineered to meet stringent safety and durability standards.

Understanding the diverse types of electrical connectors equips us to troubleshoot effectively and choose proper replacements that maintain vehicle integrity.

How Environmental Factors in Nevada Impact Electrical Connector Performance

Living and working in Nevada, we’ve seen firsthand how the state’s unique climate influences automotive electrical systems. The desert environment—with its intense heat, dry air, and occasional dust storms—can accelerate connector wear and failure.

Heat and Temperature Extremes

Nevada’s temperatures often soar beyond 100°F during summer days, placing immense stress on the plastic housings and insulation materials of electrical connectors. Over time, this heat can cause plastics to become brittle, seals to degrade, and metal contacts to oxidize.

To combat this, connectors designed for high-temperature resistance, such as those made from specialized thermoplastics and equipped with silicone seals, are essential. We have researched and found that connectors certified to meet automotive standards like IP67 (dust and water resistance) perform well under these conditions.

Dust and Debris Exposure

Dust infiltration is a common challenge in Nevada’s arid environment. Even minute dust particles inside a connector can disrupt electrical continuity or cause corrosion. That’s why dust-proof connectors or those equipped with robust sealing gaskets have become a necessity in our local automotive maintenance practices.

Moisture and Corrosion Concerns

Though Nevada is mostly dry, sudden rainstorms or washing the vehicle can introduce moisture, risking corrosion inside connectors. Properly sealed connectors with corrosion-resistant metal contacts prevent short circuits and signal degradation.

By understanding these environmental challenges, we have developed preventative maintenance tips and can recommend electrical connectors that last longer, reducing repair costs and improving vehicle reliability.

Practical Tips for Maintaining and Troubleshooting Electrical Connectors in Your Vehicle

Electrical connectors may seem simple, but neglecting their maintenance can lead to vexing vehicle issues. Here are practical tips we have relied on to keep connectors performing well.

– Regular Inspection: Periodically check connectors for signs of damage, discoloration, or corrosion. Pay close attention to areas beneath the dashboard and engine bay, where connectors face harsher conditions.

– Cleaning Connectors: Use suitable electrical contact cleaners to remove dirt and oxidation. Avoid harsh chemicals that might degrade plastic components.

– Secure Connections: Ensure connectors snap fully into place with locking tabs engaged. Loose connectors often cause intermittent electrical faults.

– Protect Against Moisture: Apply dielectric grease on connectors to repel water and prevent corrosion, especially in exposed areas.

– Replace Damaged Connectors: If a connector shows physical damage or persistent connectivity issues, replace it with high-quality parts that meet or exceed OEM specifications. Using subpar connectors can lead to further electrical troubles.

Troubleshooting common connector issues involves checking for voltage continuity with a multimeter, inspecting wiring harnesses for breaks, and testing related components. Our experience has shown that careful, systematic assessment saves time and money.

Finding Quality Electrical Connectors and Services in Nevada

Whether you’re a DIY enthusiast or a professional mechanic in Nevada, sourcing reliable electrical connectors is paramount. We’ve navigated the local market to identify trusted suppliers and service providers that understand the unique demands of automotive electrical systems here.

Choosing the Right Supplier

Look for suppliers offering connectors with proven quality certifications and strong technical support. Online platforms often provide detailed product specifications, customer reviews, and compatibility guides. We recommend prioritizing suppliers familiar with Nevada’s climate challenges to ensure durability.

Professional Installation and Repair Services

Sometimes, professional expertise is needed to diagnose complex electrical connector problems accurately. Certified automotive electricians and service centers in Nevada bring experience with local conditions and the latest diagnostic tools.

If you need expert advice or want to source premium electrical connectors designed for Nevada’s environment, visit our trusted platform at https://aspclips.com/. We have compiled resources and supplier contacts to help you get started.

Keep in mind that investing in quality connectors and regular maintenance not only improves vehicle reliability but also enhances safety on Nevada’s roads.

We’ve learned that electrical connectors, though small, play a massive role in vehicle function and longevity. By understanding their types, how environmental factors affect them, and best maintenance practices, you can ensure your car’s electrical system stays robust. Don’t wait for a minor connector issue to become a major headache—take control today.

Visit https://aspclips.com/ to explore top-rated electrical connectors and expert guidance tailored for our Nevada community. Together, we can keep your vehicle’s electrical system in peak condition for every drive ahead.