Understanding the Basics: What Makes Automotive Fasteners Essential

When it comes to building or repairing any vehicle, automotive fasteners play a critical role. These small but mighty components are responsible for holding everything together — from engine parts to body panels and interior trim. We have learned through years of experience that choosing the right fastener can mean the difference between a reliable vehicle and one prone to frequent repairs.

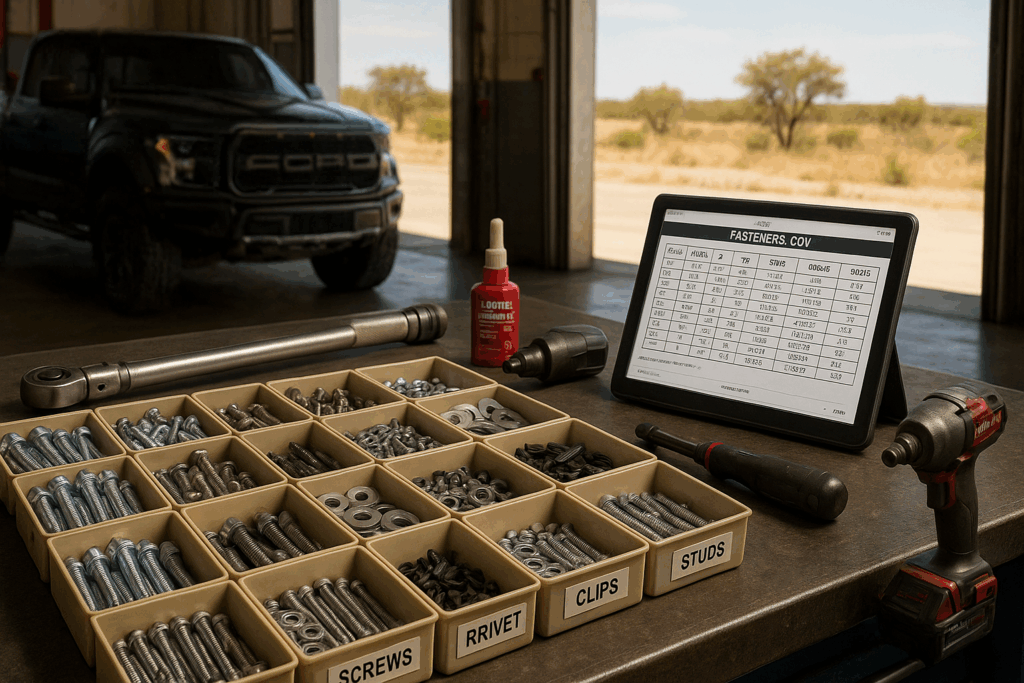

Automotive fasteners come in a myriad of types, materials, and finishes, each designed for specific applications. Common types include bolts, nuts, screws, washers, rivets, clips, and studs. Knowing these basics helps us narrow down which fastener is best suited for a particular job.

The importance of quality in automotive fasteners cannot be overstated. Inferior materials or weak fasteners can lead to failure under the stresses of driving, especially in Texas where weather extremes and road conditions add extra challenges. That’s why we emphasize understanding grades, tensile strength, corrosion resistance, and compatibility with the surrounding materials to ensure a perfect fit.

By mastering these foundational elements, we set ourselves up to make smarter choices tailored to each automotive project’s unique needs.

How to Select Automotive Fasteners for Texas Conditions

Living and working in Texas exposes our vehicles to unique stresses: intense heat during summers, occasional cold snaps, humidity, dust, and rough terrains. This climate influences how we select automotive fasteners. Here are key factors we consider:

Material Matters

– Stainless Steel: Offers excellent corrosion resistance, making it ideal for underbody parts exposed to moisture and salt.

– Zinc-Plated Steel: Provides good rust protection and is often more budget-friendly for interior or less exposed areas.

– Alloy Steel: Known for superior strength, suited for engine components and structural fasteners.

– Nylon and Plastic: Used for clips and trim fasteners where flexibility and vibration resistance matter.

Choosing the Correct Grade and Strength

Automotive fasteners come in different grades, indicating their tensile strength. For example:

– Grade 5: Medium strength for general automotive use.

– Grade 8: High strength for critical engine parts or suspension.

We always verify the manufacturer’s specifications to match the grade to the application, ensuring safety and durability.

Corrosion Resistance in Texas’ Varied Climate

Corrosion can weaken fasteners and cause parts to seize or fail. In Texas, especially coastal areas, we opt for fasteners with enhanced corrosion protection, such as stainless steel, magnesium, or additional coatings like zinc plating or galvanization. This helps prolong the life and maintain performance of the vehicle.

Practical Tips for Sourcing and Installing Automotive Fasteners in Texas

We have found that the right fasteners are only useful if sourced from reputable suppliers and installed properly. Here are our recommendations:

Trusted Local and Online Sources

– Local Auto Parts Stores: We patronize stores in Texas where we can inspect quality firsthand.

– Specialty Suppliers: Some Texas-based suppliers specialize in OEM or performance fasteners.

– Reputable Online Retailers: Sites like [aspclips.com](https://aspclips.com/) provide detailed product information, customer reviews, and timely shipping.

Installation Best Practices

– Follow Manufacturer Torque Specs: Over-tightening or under-tightening can damage components or cause failure.

– Use Proper Tools: Torque wrenches, thread lockers, and fastener-specific drivers ensure secure and precise installation.

– Clean Threads Before Installation: Dirt or rust impacts thread engagement and clamping force.

– Replace Fasteners When Recommended: Some automotive fasteners, especially those in suspension or brake systems, should be replaced rather than reused to maintain safety.

Tips for Organizing and Managing Fasteners

For enthusiasts and professionals alike, organizing automotive fasteners saves time and reduces errors. We use compartmentalized storage bins labeled by type and size. Keeping an inventory log also helps avoid last-minute trips during busy repair jobs.

Navigating Common Challenges with Automotive Fasteners

In our experience, several challenges frequently arise when working with automotive fasteners, especially under Texas conditions. Addressing them proactively ensures smooth projects.

Dealing with Rusted or Seized Fasteners

– Penetrating Oils: Products like PB Blaster or WD-40 can help loosen stuck fasteners.

– Heat Application: Carefully applied heat can expand metal and break corrosion bonds.

– Impact Tools: Impact wrenches provide controlled force that can dislodge tight fasteners.

– Cutting or Drilling: As a last resort, we carefully cut or drill out rusted fasteners to avoid damaging surrounding parts.

Mismatched or Wrong-Sized Fasteners

Using incorrect sizes or thread types can cause stripping or weak connections. We always measure fastener dimensions carefully, use thread gauges, and cross-reference with vehicle specs.

Fastener Compatibility with Materials

Certain fasteners can cause galvanic corrosion when paired with dissimilar metals. For example, aluminum and steel in contact can corrode faster. We select fasteners with compatible materials or apply protective coatings to prevent this issue.

Tips for Specialty Automotive Applications

– High-Temperature Areas: Use fasteners rated for extreme heat in exhaust or engine compartments.

– Vibration-Prone Areas: Employ locking nuts, lock washers, or thread-locking adhesives for added security.

– Body Panels and Trim: Choose fasteners that provide secure attachment without damaging paint or plastics.

The Value of Expertise and Quality Assurance in Texas’ Automotive Fastener Market

Navigating automotive fasteners in Texas’ vast market requires expert knowledge and assurance of quality. We value partnerships with suppliers who provide:

– Certification of Material and Grade: Ensures fasteners meet strength and safety standards.

– Consistent Quality Control: Avoids batch variations that might undermine reliability.

– Technical Support: Advises on the best fastener for specific projects.

– Custom Solutions: For unique applications, custom fasteners or clips made to spec can save time and improve performance.

We encourage local Texas mechanics, automotive enthusiasts, and professionals to stay informed about the latest innovations in fastener technology and materials. Modern fasteners often incorporate coatings, improved designs, and lightweight alloys that optimize vehicle safety and longevity.

For those looking to source high-quality automotive fasteners with expert guidance, ASP Clips is a trusted resource offering a wide selection tailored for Texas conditions and applications.

As we continue working on a variety of vehicles under Texas’ demanding environments, our commitment to using the right automotive fasteners remains a cornerstone of quality and reliability.

Using the right automotive fasteners significantly impacts vehicle performance and safety. By understanding material types, grades, climate considerations specific to Texas, installation best practices, and common challenges, you’re well-equipped to make confident choices.

If you’re ready to upgrade your automotive fastener supply or need expert advice tailored to your project, visit https://aspclips.com/ to explore quality options available today. Our passion is helping you keep your vehicle secure and running smoothly with the right fasteners chosen the right way.