Understanding the Role of Automotive Fasteners in Vehicle Maintenance

When we talk about vehicle maintenance, automotive fasteners might not be the first thing that comes to mind. Yet, they are the unsung heroes holding every component of a vehicle together. In Texas, where roads can range from dusty country paths to bustling highways, the reliability of automotive fasteners is crucial. These small but mighty parts ensure that everything from the engine to the body panels stays securely attached and functions properly.

Automotive fasteners encompass a broad category, including bolts, nuts, screws, clips, and rivets, each designed for specific applications. Whether you are a professional mechanic or a car enthusiast performing DIY repairs, understanding how these fasteners work can save you time, money, and frustration. We have seen many cases where simple issues like a loose bolt or worn clip led to bigger mechanical troubles because the importance of automotive fasteners was underestimated.

A solid grasp of automotive fasteners allows us to select the right element for the job, achieve proper torque settings, and avoid unnecessary damage during repairs. It’s an essential part of keeping vehicles safe and roadworthy, particularly in Texas, where varying climates and driving conditions put extra stress on automotive assemblies.

Types of Automotive Fasteners and Their Applications

Choosing the right fastener depends on where and how it will be used. Over the years, we have categorized automotive fasteners into several key types, each with unique properties.

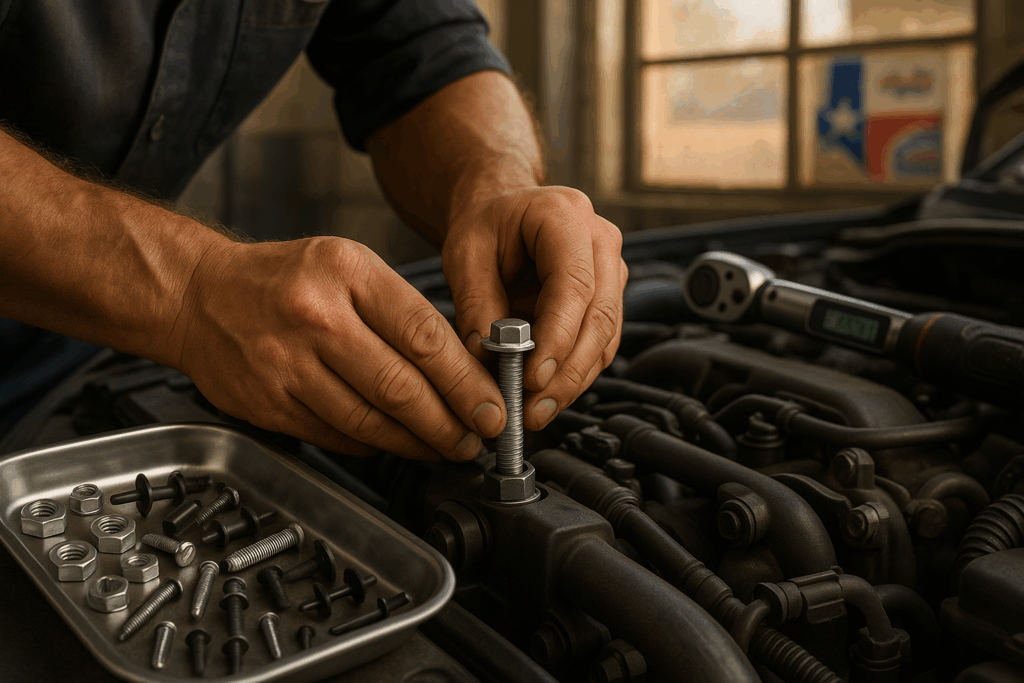

Bolt and Nut Assemblies

These are the most common automotive fasteners. Bolts come in various grades and finishes tailored for specific uses. For instance, high-strength bolts are essential for engine components where vibrations and heat are intense. Texas mechanics regularly work with SAE and metric bolts, so knowing the difference helps prevent improper replacements.

– Hex bolts for general fastening

– Flanged bolts to distribute load

– Lock nuts to resist loosening due to vibration

Clips and Retainers

Clips are often overlooked but play a vital role in retaining trim, panels, or wiring harnesses. We have observed that the right clip replacement can prevent rattling noises and secure sensitive electronic components. In Texas, where dust infiltration is a concern, properly installed clips help maintain vehicle integrity.

– Panel clips to hold body parts

– Spring clips for flexible connections

– Push retainers used in interior assembly

Specialized Fasteners

– Rivets: Often found in structural parts where permanent fastening is needed.

– Threaded inserts: Used in plastic components to provide a durable thread.

– Automotive adhesives combined with fasteners improve sealing and vibration damping.

Proper identification of the type and material is critical. For example, stainless steel fasteners resist corrosion better, which is beneficial in humid areas of Texas, whereas zinc-plated fasteners are more economical but less resistant.

Best Practices for Installing and Maintaining Automotive Fasteners

We’ve learned that the correct installation and upkeep of automotive fasteners can dramatically affect vehicle performance and safety. Here are our key strategies:

Pre-Installation Checks

Before installation, always inspect the fastener for any defects, rust, or wear. Reusing old fasteners without checking can lead to failure. In Texas, where dust and road salts are common, corrosion is a major issue for fasteners exposed underneath vehicles.

– Clean threads to ensure proper torque

– Use thread lockers if required to prevent loosening

– Replace any fasteners that show deformation

Proper Torque Application

Over-tightening can strip threads or break bolts, while under-tightening risks loosening. We recommend using a calibrated torque wrench and following manufacturer specifications. Our Texas workshops follow these practices rigorously to avoid costly repairs.

– Follow OEM torque specs for each fastener size and type

– Incrementally tighten in a crisscross pattern when applicable (e.g., cylinder heads)

– Recheck torque after initial use to account for settling

Routine Inspection and Replacement

Fasteners undergo stress cycles and environmental exposure, leading to fatigue or corrosion over time. Regular inspection during tune-ups or servicing can catch early signs of failure. Our routine maintenance guides in Texas include checking the tightness and condition of critical fasteners such as those in suspension and brake systems.

– Look for rust, thread damage, and looseness

– Replace fasteners during major repairs or panel replacements

– Use OEM or high-quality aftermarket replacements

Automotive Fasteners and Vehicle Maintenance Challenges in Texas

Texas presents unique conditions that impact automotive fasteners. Between hot summers, humidity in coastal regions, and dusty environments, we have to adapt maintenance routines to keep vehicles safe.

Environmental Factors Affecting Fasteners

– Heat: High temperatures can cause metal expansion and stress on fasteners.

– Moisture: Coastal areas like Houston see more corrosion due to salty air.

– Dust and dirt: Central Texas roads can be dusty, which can infiltrate joints held by clips and fasteners, impacting their function.

Our approach in Texas has been to prioritize corrosion-resistant fasteners when environmental exposure is high. For example, switching to stainless steel or coated fasteners helps in coastal service areas. Additionally, we apply anti-seize compounds to prevent galling and ease future disassembly.

Supply and Accessibility of Quality Fasteners in Texas

One challenge we have faced is sourcing authentic and high-quality automotive fasteners. Counterfeit or low-grade parts can compromise safety. By working with trusted suppliers and manufacturers, we ensure fasteners meet the necessary standards.

– Local Texas distributors who specialize in automotive fasteners

– OEM fasteners for critical applications

– Keeping inventory of common sizes and types for quick repairs

This approach allows us to reduce downtime and enhance vehicle reliability, crucial for Texas drivers who often rely on their vehicles for heavy use.

Technological Innovations and Trends in Automotive Fasteners

The automotive industry is evolving, and so are the fasteners. We’ve embraced newer technologies to improve vehicle maintenance experiences.

Advanced Materials and Coatings

Innovations include fasteners made from titanium alloys, composites, and advanced coatings that resist corrosion and fatigue better than traditional steel. In Texas, where durability is key, these materials extend service life and reduce maintenance intervals.

Smart Fasteners and Tracking

One exciting development is the integration of sensors into fasteners to monitor torque and detect loosening in real-time. Though still emerging, we see this technology becoming valuable, especially for fleet maintenance in Texas where uptime is critical.

Automation in Fastener Installation

Robotic tools and automated torque systems increase precision in automotive assembly and repair. We have integrated some of these tools into our Texas garages to enhance efficiency and consistency.

These advancements underscore the importance of staying current with fastener technology to maintain vehicles safely and effectively.

Final Thoughts

We’ve unpacked how automotive fasteners are fundamental to vehicle safety and maintenance, especially here in Texas with its unique environmental challenges. Understanding the types, correct installation techniques, and material choices can greatly improve vehicle reliability. As technology progresses, staying informed about innovations in automotive fasteners will keep your maintenance routine ahead of the curve.

If you’re looking for expert advice or quality automotive fasteners in Texas, we are ready to help. Explore our resources or contact us at https://aspclips.com/ to get the best fasteners tailored for your needs. Don’t overlook these small components—they make a big difference on the road!