The Role of Chemical Adhesives in Modern Vehicle Repair

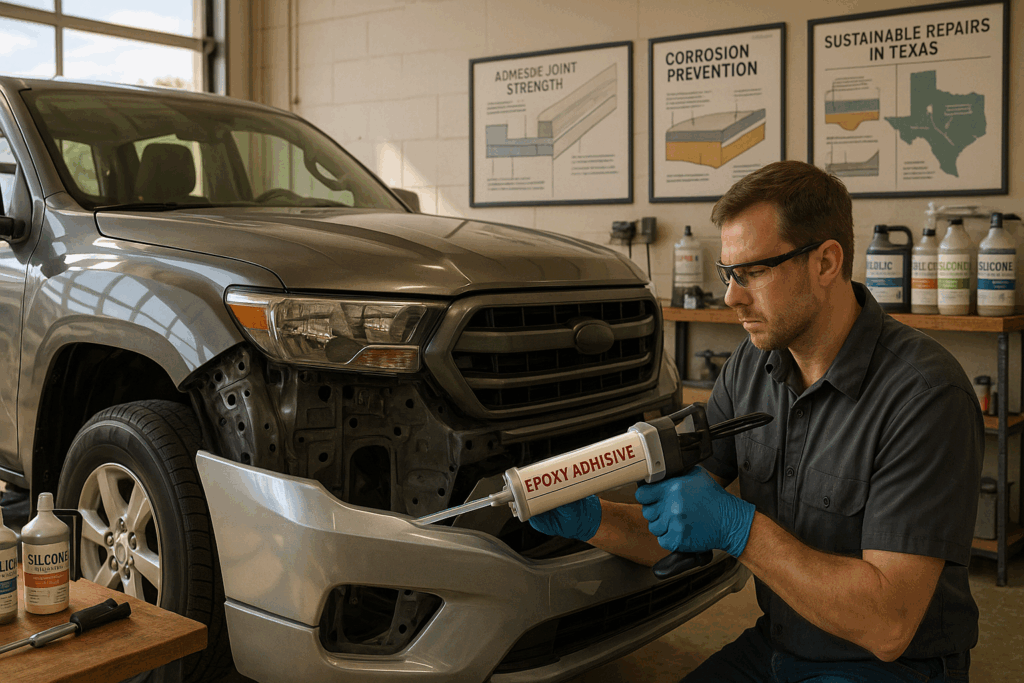

When it comes to repairing vehicles, we often think about welding, riveting, or using mechanical fasteners. However, chemical adhesives have become indispensable in the automotive repair industry, particularly here in Texas where vehicle maintenance needs to withstand diverse climate conditions and rugged use. Chemical adhesives allow us to bond materials seamlessly without the drawbacks of traditional fasteners — no drilling holes or risking metal fatigue.

Chemical adhesives provide strong, durable joins between parts made from various materials like metal, plastic, glass, and composites. This versatility means repairs can be more precise and less invasive. For instance, when replacing a cracked windshield or repairing a plastic bumper, adhesives enable us to restore the vehicle’s integrity without compromising its design or safety features. Our experience has shown that using chemical adhesives results in better stress distribution in joints, which contributes to longer-lasting repairs.

We have adopted chemical adhesives because they adhere efficiently under different environmental conditions common in Texas, such as high heat in the summer and cold winters. Their resistance to vibration and shocks is crucial for vehicles that often endure bumps and uneven terrains. By mastering these chemical bonding techniques, we’ve enhanced repair quality while also reducing labor time, offering our customers quicker turnaround and more affordable service.

Key Advantages of Chemical Adhesives Over Traditional Repair Methods

The transition to chemical adhesives in vehicle repair brings several compelling benefits that we rely on every day in our Texas workshops. Understanding these advantages helps us appreciate why chemical adhesives are essential for keeping vehicles safely on the road.

– No structural damage: Unlike drilling or welding, adhesives do not require holes or heat application that can weaken metals or other components.

– Weight reduction: Adhesive bonding eliminates the need for heavy mechanical fasteners, helping maintain the vehicle’s lightness which improves fuel efficiency.

– Enhanced joint strength: Chemical adhesives provide superior load distribution, preventing cracks and fractures that can occur around fastener holes.

– Corrosion prevention: Traditional fasteners can trap moisture and cause rust, while adhesives form a sealed bond preventing corrosion.

– Compatibility with dissimilar materials: We often join aluminum to plastic, glass to metal, or composites using specialized adhesives optimized for each material’s properties.

– Flexibility for complex shapes: The ability to bond irregular surfaces means we can address repairs that otherwise would be difficult or impossible.

An example of these benefits is in repairing body panels on a Texas vehicle after collision damage. Using adhesives allows us to bond panels cleanly without warping or deforming them. This process also improves the vehicle’s ability to absorb impacts safely in the future, meeting safety regulations and customer expectations alike.

Choosing and Applying Chemical Adhesives for Vehicle Repairs in Texas

Selecting the right chemical adhesive and applying it correctly is critical to achieving a durable repair that can endure Texas’ challenging environment. We’ve learned through experience and research how multiple factors influence this choice.

Types of Chemical Adhesives Commonly Used

We typically work with several types of chemical adhesives tailored for automotive repair:

– Epoxy adhesives: Excellent for structural bonds, providing high strength and chemical resistance.

– Polyurethane adhesives: Offer flexibility and good impact resistance, suitable for body panels and seals.

– Acrylic adhesives: Fast curing and strong, often used for bonding metals and plastics.

– Silicone adhesives: Used primarily for sealing and weatherproofing due to their elasticity.

Important Considerations for Effective Use

To maximize the performance of chemical adhesives, we always emphasize:

– Surface preparation: Cleaning, degreasing, and sometimes sanding ensure the adhesive bonds well.

– Application environment: Temperature and humidity levels in Texas can affect curing time and bond strength.

– Adhesive curing: Proper curing time and techniques such as clamping or spacing maintain joint integrity.

– Compatibility testing: Verifying adhesive suitability with specific vehicle materials avoids failures.

By adhering to these practices, we ensure that every chemical adhesive repair meets industrial standards and customer satisfaction.

Impact of Chemical Adhesives on Vehicle Repair Sustainability and Cost in Texas

One aspect we value highly in using chemical adhesives is their contribution to more sustainable and cost-effective vehicle repairs. In Texas, where vehicle fleets are vast and varied, keeping repair expenses reasonable while supporting environmental responsibility is essential.

Using chemical adhesives helps us reduce waste by enabling component replacement instead of full part swaps. This minimizes landfill disposal and conserves resources. Additionally, because chemical bonding avoids intense heating or mechanical damage, repaired parts retain more of their original properties and last longer.

From a cost perspective, we’ve seen that chemically bonded repairs often require less labor and fewer parts. Quicker repairs reduce workshop downtime and allow vehicle owners to get back on the road faster. The precision of adhesive repairs also decreases the likelihood of subsequent repairs due to failure.

Furthermore, many chemical adhesives are now formulated with lower volatile organic compounds (VOCs) and environmentally safer chemicals, aligning with Texas’ increasing regulatory focus on sustainable automotive practices.

Future Trends and Innovations in Chemical Adhesives for Texas Auto Repair

Looking ahead, chemical adhesives are poised to become even more integral to vehicle repair and manufacturing. We stay informed about emerging trends to continuously improve our service quality here in Texas.

One promising innovation is the development of “smart adhesives” that can change properties based on temperature or stress, providing adaptive repair solutions that enhance vehicle safety.

Another trend is adhesives designed for advanced lightweight materials like carbon fiber composites, which require bonding solutions capable of maintaining strength without adding bulk or weight.

We also expect further integration of eco-friendly adhesive chemistries, driven by both consumer demand and stricter environmental policies.

Our passion is to stay at the forefront of these advances, ensuring that Texas vehicle owners benefit from the most effective, durable, and sustainable chemical adhesive technologies available.

Exploring how chemical adhesives can revolutionize vehicle repair in Texas is an exciting journey. We invite you to learn more about implementing these innovative techniques and trust in our expertise to keep your vehicle performing at its best.

To discuss your next vehicle repair or get expert advice on chemical adhesives, visit us at https://aspclips.com/ and reach out today. Our team is ready to provide tailored solutions that meet your needs with the highest standards of quality and care.